|

We begin with a stack of panels..

insuring the panels are in proper numerical order.. very important!

There is a label on each to assist in that and also I found it

pays to keep your eyes open and double check everything. Failure

to do that cost me dear in one instance and succeeding at being

alert saved me on another. More below on that. Notice the shapes

revealed in the routing. There is a small bulkhead at lower left. |

|

The press comes from ATL and it's

use is incorporated into the price of your panel purchase. The

press surfaces are heated by water that circulates through the

press heads. It needs several hours to warm up. Overnight is

good. I set up a table to prep

one panel whilst the other is in the "Z" press. After

squirting the glue on both edges I spread with a paint brush

as well. |

|

Next panel ready to be flipped over

to match the other panel. |

|

Then push and wiggle side to side

to evacuate any air and .... |

|

check alignment by the edge and...

I found out later, keep an eye on the routed lines as well. Make

sure those lines match as well as the edge. Those are Teflon

coated press surfaces but when they get used a bit a spray of

silicone does wonders. |

|

Then pump the hydraulic press to

about 800lbs on the gauge and allow about one minute for every

mm of panel thickness. |

|

Whilst the previous panel is in

the press I squirt glue onto the next panel after dusting off

any debris. Not everyone does, but I like to spread the glue

after squirting on with a paint brush. The glue is two part epoxy

with the container making the automatic allotment and the tip

is the mixing devise.

This is also the time when I strip off

the peel ply used as a masking surface.. see further below for

an explanation........... |

|

I used a cooking timer and when the

bell rings.. release the pump and raise the press and move the

panel forward to prepare for the next one. |

|

Keep going.. and you will see the

individual panels being revealed. Again, be careful to insure

the panels are glued in the correct order. A note here.. the

press isn't required for this job, it just makes the process

faster. The heat makes the glue go off much faster. The job can

be done with timber strips and screws to hold the lot together

whilst the glue sets or see the link above on scarfing. |

|

My first bunch of panels were full

length sections so I had a looonnngg section to push along before

I could start cutting them free. |

|

The electric saw lasted about 10

minutes before it carked it.. did most of the panels with a regular

hand saw. When sawing insure the surface facing the panel section

is flush or even concave as a high spot on the edge of a panel

will disrupt the fit when assembling. |

|

Tricks, Fixes and Problems |

|

I had some trouble pushing and sliding

to get air out (as mentioned earlier) until there was a lot of

panels to provide some weight. Couple of clamps took care of

that. |

|

Here is the method that I was

shown by a local builder for leaving a clean joint. Start by

scoring a line in the peel ply parallel to the edge and full

length.

For those that don't know what peel

ply is... it is a nylon cloth that covers the panels to leave

a clean and workable surface. When removed it takes contaminants

with it that result from the curing of the resin and leaves a

surface that doesn't require sanding for further work. |

|

Then squirt in the glue and spread

with paint brush (I do anyway) and go through the pressing steps

as described earlier. This is also a view of a perfect scarf

joint. This is what they are supposed to look like. A good firm

'lip' on the fibre glass edge and the inside facing surface should

be consistent, straight and cleaned off back to a few mm greater

width then the fibre glass 'lip' edge. |

|

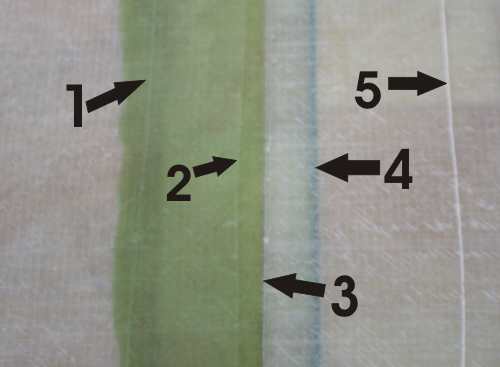

This is what it can look like

then, after going through the press.

1. is a scoring line, this one covered

in glue but no worries. Find a clean corner and pull the peel

ply off.

2. the end of the peel ply. between

2 and 3 is where the glue will remain after stripping off the

mask. 3.the edge of the 'lip' of glass.

4. the actual join of balsa under the

glass showing the line of glue there.

5. the scoring on the other side. The

peel ply will be removed between 5 and 3. |

|

With peel ply stripped away as described

above, this is what you get. Very clean and easy to fair surface.

BUT.. there is sometimes a but... this technique combined with

some factory defects caused a lot of pain in the arse before

the defects were spotted... more later. |

|

Sometimes the glue gun and mixing

tip don't work well. Parts A and B are different colour and this

shows inconsistency in colour indicating poor mix. I mixed as

best I could on the surface with the paint brush and it seemed

to work OK. just don't trust the gun.. always check. |

|

Here is where I had a win!! The panels

were miss-aligned. If I had aligned in the press by the edge,

which is the normal way, it would have been a disaster. But I

had been watching everything by then and noticed that by aligning

the edges the routed lines were just a little off. |

|

And again... after examining the

thing I think I understand why it was done but to have shipped

it off without alerting the builder to the anomaly was pretty

slack. |

|

This was a big awh SHIT! moment. Peel

ply under the glued edge. Why? How? Answer... a variety of faults.

This join is ruined and will have to

be ground away and redone leaving more fairing work. Of the

65 panels most had this problem to some degree. The first 20

or so panels were all good so this problem snuck up on me.

If I had used the method where you strip

away peel ply prior to gluing the peel ply could not have got

trapped under the glass but I would still have poor structural

joints and the addition fairing. |

|

How did it happen???

Here is one way. The line in the peel

ply was scored at the factory and was where the peel ply was

meant to be removed but it wasn't. Even if I had removed adjoining

peel ply before the gluing process this would have remained and

caused the join to fail as the peel ply would have been under

the glue.

Also note the inconsistent and ragged

scarf. |

|

Here is another way... on this one

the peel ply was scored and removed and the scarf was cut clean

and consistent. But consistanly wrong! The under side was much

shorter than the 'lip' side so once again, if not spotted there

would be peel ply under the glue again. |

|

About 35 panels had problems related

to poor scarfing. This was the worst but is a good indicator

of one type of problem. The scarf is ridiculously over cut. There

is almost no fibre glass left. Just a thread or two and the peel

ply holding the lot together. This one was so bad someone at

the factory appears to have covered it in clear packing tape

so it would get here without crumbling more. |

|

an obvious need for better quality

control. |

|

This is the most graphic example

but so many had been over cut. Some would look OK at a glance

but when closely inspected would reveal that most of what you

were seeing was peel ply and little fibre glass left. This makes

for a substancialy weaker joint. It would need to be taped and

then the extra fairing. |

|

I had several (5 at last count) of

these. Gross wrinkles caused by the resin going off whilst the

panel was still being worked at the factory. The issues up front

are.. heavier panels (resin rich) in what is supposed to be a

light weight product, more fairing work and the peel ply can

get stuck underneath the wrinkles and be very difficult to clean

out, even requiring grinding off some glass to get it. |

|

More of same... |